Mastering In-Mold Decorations: Methods, Fads, and Ideal Practices for Ideal Outcomes

In the realm of production, the art of in-mold decorations stands as an essential element of product style and production. In-Mold Decorations. By diving right into the methods, fads, and best methods that underpin successful in-mold design processes, services can unlock a realm of possibilities that not just boost the aesthetic allure of their items but likewise simplify manufacturing effectiveness and bolster consumer involvement.

Product Option

Product option is an essential element of grasping in-mold designs, as it directly affects the high quality and durability of the end product. When selecting products for in-mold decorations, it is vital to consider aspects such as compatibility with the molding process, the wanted aesthetic outcome, and the environmental conditions the product will encounter. Thermoplastic materials like polypropylene, polycarbonate, and abdominal are frequently made use of for in-mold decors because of their versatility and capability to achieve detailed designs. These materials provide superb moldability, making it possible for suppliers to produce intricate shapes and patterns with accuracy.

In addition, the chosen material needs to possess good adhesion residential properties to make sure that the design adheres firmly to the substratum during the molding procedure. Bond between the product and the decor is vital for protecting against delamination and ensuring resilient visual appeal. In addition, products with high heat resistance are favored for in-mold decors, particularly for products that will certainly be exposed to raised temperature levels throughout their lifecycle. By carefully picking the proper product for in-mold designs, suppliers can boost the general quality and durability of their items, meeting the expectations of both customers and end-users.

Layout Innovation

An important variable in progressing the area of in-mold designs is the constant exploration and application of style innovation techniques. Layout technology plays a critical role in enhancing the aesthetic allure, performance, and overall top quality of items produced using in-mold design procedures. By incorporating cutting-edge layout elements, manufacturers can differentiate their products on the market, draw in consumers, and remain ahead of rivals.

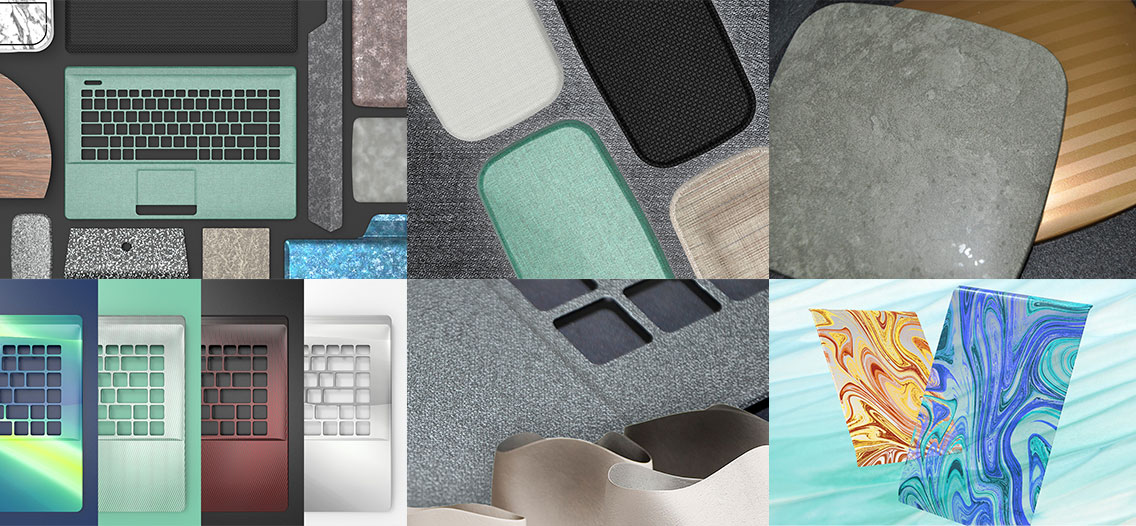

Among the essential facets of design advancement in in-mold decors is the assimilation of detailed patterns, structures, and graphics that were previously testing to accomplish with traditional decor methods. Advanced modern technologies such as 3D printing and digital style devices enable developers to create facility and detailed layouts that can be flawlessly transferred onto shaped components. Furthermore, using lively colors, metallic coatings, and special impacts like gloss or matte textures can better boost the aesthetic charm of in-mold decorated items.

In addition, layout advancement extends past aesthetic appeals to encompass practical enhancements such as ergonomic forms, integrated features, and personalized components that satisfy specific user demands. By welcoming design development, suppliers can unlock brand-new opportunities for imagination, item, and personalization distinction in the affordable landscape of in-mold decorations.

Manufacturing Effectiveness

Reliable manufacturing procedures are vital for equating the innovative styles developed in the field of in-mold designs into top quality ended up items that satisfy market needs and customer expectations. In the realm of in-mold decorations, manufacturing efficiency includes different vital facets that add to the total success of the production procedure. One vital aspect is the optimization of mold design and tooling to make certain accurate and Full Article smooth design transfer onto the end product. By fine-tuning mold arrangements and purchasing top quality tooling materials, suppliers can improve efficiency and consistency in production.

Additionally, carrying out automation and robotics in the assembly line can substantially boost effectiveness by simplifying recurring jobs and decreasing the margin of mistake. Automation not just speeds up the production process however additionally boosts accuracy and repeatability, resulting in a more top quality and uniform final product. Adopting lean manufacturing principles, such as just-in-time stock management and waste decrease strategies, can additionally improve production efficiency by reducing downtime and enhancing source use. On the whole, a holistic approach to manufacturing efficiency is critical in maximizing the capacity of in-mold decor methods and attaining ideal results in the affordable market landscape.

Quality Assurance Actions

What are the vital strategies for guaranteeing stringent quality assurance actions in the realm of in-mold decors? Quality assurance steps are extremely important in in-mold decor processes to make certain the production of top notch and flawless completed products. One important strategy is the application of extensive evaluation protocols at every stage of the production process. This involves performing thorough aesthetic assessments, dimensional checks, and shade consistency assessments to recognize any incongruities or defects early on.

Using sophisticated technologies such as automatic inspection systems can likewise boost the high quality control procedure by giving precise and reliable data for analysis. These systems can detect blemishes that might be missed by hand-operated inspections, thereby boosting general item quality and uniformity.

Normal training and growth programs for employees associated with the in-mold decor procedure can additionally add to maintaining top notch criteria. By enlightening staff on ideal techniques, top quality expectations, and the importance of attention to information, business can cultivate a culture of top quality consciousness throughout the company.

Customer Allure

To boost the bankability of in-mold design items, catering and recognizing to customer preferences play a crucial duty in determining their charm and success. Consumer allure in in-mold decors is affected by various elements, consisting of style visual appeals, shade options, sturdiness, and general functionality. Consumers are significantly seeking personalized and unique items that reflect their originality and style. Supplying personalization options such as personalized styles, color click over here variations, and textural components can substantially enhance the allure of in-mold design items.

Final Thought

In-mold designs offer a reliable and functional way to improve item visual appeals. By very carefully choosing materials, accepting innovative styles, optimizing manufacturing procedures, executing top quality control actions, and focusing on customer allure, makers can achieve ideal results. It is critical for business to constantly adapt and enhance their strategies to stay competitive out there. In-Mold Decorations. Understanding in-mold decors calls for an alternative strategy that thinks about all aspects of the manufacturing procedure to make certain success.

In the realm of manufacturing, the art of in-mold read designs stands as a crucial facet of item style and production. Design advancement plays an essential function in improving the aesthetic appeal, capability, and total top quality of products manufactured using in-mold design procedures.One of the vital elements of design technology in in-mold decors is the assimilation of intricate patterns, appearances, and graphics that were formerly challenging to accomplish with conventional design methods.Effective manufacturing procedures are crucial for equating the ingenious layouts developed in the field of in-mold designs right into high-grade finished items that meet market needs and customer expectations. Offering personalization options such as personalized designs, color variants, and textural aspects can considerably enhance the allure of in-mold design items.